"You have a deep understanding of application scenarios!"

"This robot boasts many marvelous innovations that perfectly align with manufacturing needs!"

"Your robots are truly applicable in industrial settings!"

—Feedback from professionals and clients at WRC

On August 12, the 2025 World Robot Conference (WRC) concluded in Beijing. At this globally acclaimed robotics event, PL-Universe accomplished two major milestones - the worldwide debut of PL-Universe ProWhite, an industrial-grade wheeled embodied intelligent humanoid robot integrating flexibility and precision; and the launch of its Global Partner Recruitment Program. With cutting-edge technology and an open approach, the company earned high recognition from professional attendees and clients, adding a new milestone to the future of industrial-grade embodied intelligence.

01

Debut Spotlight: PL-Universe ProWhite Robot Defines "Industrial-Grade Capability" with Three Demos

As a core highlight of this year's WRC, the debut of PL-Universe ProWhite Robot has drawn significant attention within the industry. Three core demos at booth A134 transformed the concept of "implementing robots in industrial scenarios" into reality:

Demo 1: Random Screw Fastening Process

PL-Universe ProWhite Robot boasts ultra-high precision as its core competitive advantage, with performance parameters on par with leading industrial robots—achieving a repeatable positioning accuracy of ±0.05mm. Equipped with adaptive dynamic precision compensation technology, it can automatically calibrate positions through dimensional measurements, ensuring precise completion of operations.

During the live demo, ProWhite Robot first extended its 7-degree-of-freedom dual arms, then used the gripper equipped with high-precision positioning cameras to scan and identify objects, and then immediately switched to the screw fastening tool gripper to begin operations. It took only 12 seconds to finish the fastening of four precision components with perfect alignment. This operation was deliberately slowed down for the audience to observe clearly and can run twice as fast in actual production!

With this core advantage, ProWhite Robot effortlessly handles high-precision scenarios such as precision component assembly and small part inspection, meeting the stringent quality and precision standards demanded by industrial production.

Demo 2: Vacuum Cleaner Component Assembly and Inspection

In the second demo, ProWhite Robot showcased the complete assembly and inspection process of vacuum cleaner components: After identifying objects through high-precision positioning cameras mounted on its arms, ProWhite Robot used modular end-effector grippers to steadily grasp the component cover and precisely align it with the product base.

After assembly, ProWhite Robot immediately used the camera-equipped gripper to inspect the component gaps. If a defect was found, it automatically activated edge algorithms for reassembly. However, after real-time spatial coordinates collection and dynamic process verification, ProWhite Robot consistently achieved an assembly yield rate of 99%, delivering a highly reliable performance.

Demo 3: Dual Functionality – "One Robot, Two Uses"

PL-Universe ProWhite Robot features an innovative self-developed parent-child separation design, enabling efficient collaboration through "one machine, two uses":

After arriving at the workstation, the wheeled embodied main unit could perform process operations in place like a human.

Meanwhile, the mobile chassis detached from the main body, transforming into a "super assistant" - it both helped the ProWhite Robot group collect data and handled the loading/unloading of empty and full material bins, streamlining the workshop's internal logistics chain.

This design forms a closed loop system for fully automated operations, driving the production process toward digitalization, automation, and informatization while significantly improving process consistency and production efficiency.

02

An Open Approach Brings Win-Win Cooperation: Global Partner Recruitment Program Launched to Jointly Solve Industrial Scenario Challenges

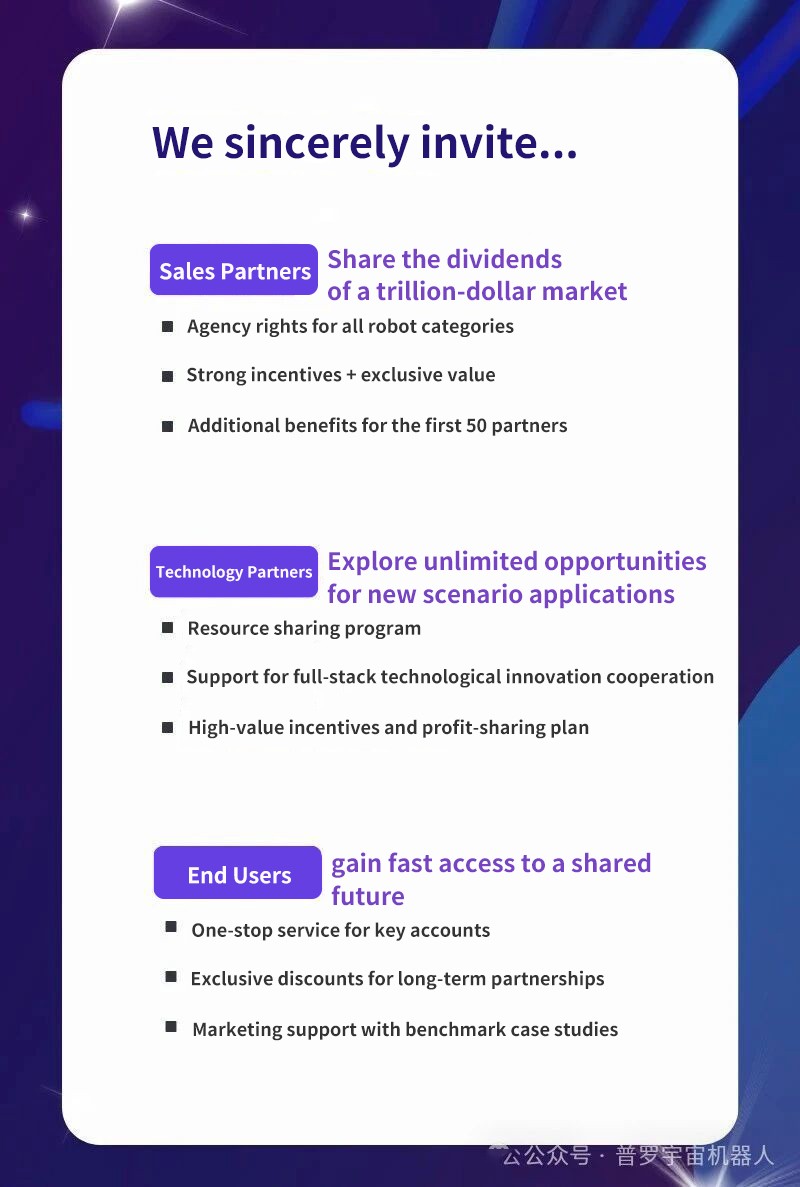

At the WRC, PL-Universe officially launched its "Global Partner Recruitment Program", introducing customized cooperation solutions for three types of partners and leveraging resources, technology, and incentives to drive industry collaboration:

"The widespread adoption of wheeled embodied robots in industrial scenarios has never been a solo journey for any single company," the founder of PL-Universe stated at the event. "We open our resources and share benefits in the hope of realizing the vision of "freeing our hands with robots" faster by working with partners."

03

The End is Just the Beginning: From Exhibition to Workshop, Bringing Industrial Embodied Intelligence to More Application Scenarios

Though the 5-day WRC has concluded, the "implementation journey" of PL-Universe is just beginning. During the exhibition, companies from 3C electronics, automotive, and other manufacturing industries engaged in in-depth discussions about the technical details and implementation scenarios of ProWhite Robot. Many clients spoke highly of PL-Universe Robotics.

"You have a deep understanding of application scenarios!"

"This robot boasts many marvelous innovations that perfectly align with manufacturing needs!"

"Your robots are truly applicable in industrial settings!"

—Feedback from professionals and clients at WRC

Among the many robots at the event capable of running and jumping, the one that could "screw in screws" on-site stood out, attracting attention from numerous media outlets.

PL-Universe believes that from the spotlight at WRC to factory production lines, the future of industrial-grade embodied intelligence lies not in academic papers, but in every tightened screw and every precise assembly.

We look forward to collaborating with more partners to bring PL-Universe ProWhite Robot to production lines in factories worldwide. Through technological innovation, we aim to accelerate the deployment of industrial-grade wheeled embodied robots across diverse scenarios, empowering a genuine upgrade from "automation" to "intelligence" in smart manufacturing.

扫码关注